It is a term and condition of your ongoing use of the Zoom2u Pty Ltd (Zoom2u) Platform conducting business with you that you comply with this Chain of Responsibility Compliance Policy. The terms of this policy will prevail to the extent of any inconsistency with any other agreed terms (whether before or after these terms). In any event, you have an independent legal obligation to comply with the Chain of Responsibility laws discussed in this policy.

Purpose

This policy sets out Zoom2u’s expectations of the Couriers and Customers that use the Platform in relation to compliance with the CoR laws and the action that Zoom2u will take in the event of non-compliance. This policy is also a useful guide to the Chain of Responsibility laws and requirements for Couriers and Customers.

The Chain of Responsibility (CoR) laws means the Heavy Vehicle National Law and Regulations and Road Traffic (Administration) Act 2008 (WA) and Road Traffic (Vehicles) Act 2012 (WA) and any other similar laws in any State/Territory (or any replacement or modification thereof)). The CoR laws encompass heavy vehicle:

- mass, dimension and load restraint requirements; and

- speeding, fatigue and (from mid-2018) vehicle maintenance management requirements.

The CoR laws apply to the movement of any cargo by heavy vehicle on the road. A heavy vehicle is any vehicle or combination with a Gross Vehicle Mass (maximum loaded mass, not merely the tare weight of a vehicle or combination) of 4.5 tonnes or more. In Western Australia, the CoR laws relating to mass, dimension and load restraint also apply to the movement of any cargo by light vehicle.

Breach of the CoR laws can result in infringement notices, fines, criminal prosecutions, commercial benefits penalties, compensation orders, prohibition orders and supervisory intervention orders.

Compliance with CoR laws is the responsibility of every party in the chain. Zoom2u takes compliance with the CoR laws very seriously, requires its business partners to comply and will not condone, endorse or reward non-compliance.

Scope

This policy applies to the performance of all Bookings made using the Platform which are intended to be or are performed by a heavy vehicle or, in the case of Western Australia, any vehicle.

This policy and the CoR laws cover the operations and conduct of all parties to the road transport supply chain (see further ‘Roles and Responsibilities’ below).

However, this policy is not exhaustive and all persons remain responsible for ensuring their own compliance with the CoR laws. To this end, all parties must familiarise themselves with the laws and obligations which apply to them and their operations.

CoR laws components

The CoR laws cover:

| Party/Role | Description |

| Mass | Loads must be within maximum legal gross vehicle and axle load limits, either generally or under any permit or notice and within the maximum load mass of any freight container |

| Dimension | Loads must be within maximum legal height, length, width and overhang limits, either generally or under any permit or notice |

| Load restraint | Loads must be secured within freight containers and within/on vehicles so that they do not make the vehicle unstable or unsafe and are secure and not likely to shift or fall out of/off the vehicle |

| Fatigue management | Vehicles may only hit the road where drivers are not adversely affected by fatigue and are within their maximum permitted driving hours, either generally or under any fatigue accreditation scheme |

| Speed management | All journeys must be capable of being completed and actually completed within legal speed limits |

| Vehicle maintenance | All vehicles must comply with any applicable heavy vehicle standards and at all times during use be properly maintained and roadworthy |

Roles and Responsibilities

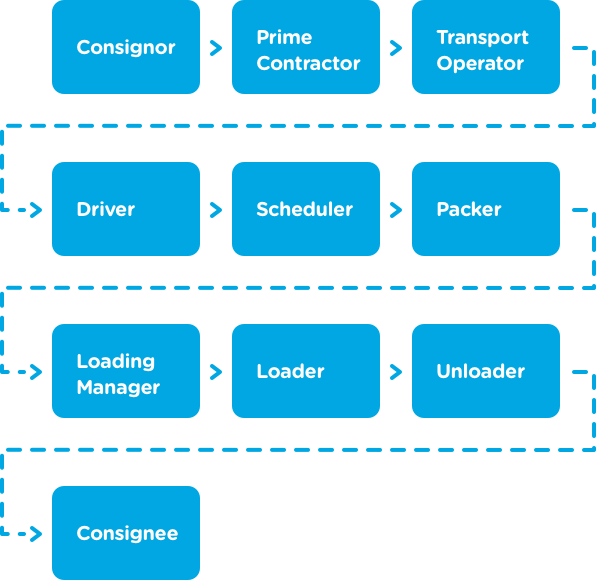

The CoR laws cover the operations and conduct of all parties to the road transport supply chain:

Essentially any person who:

- consigns, packs/prepares, schedules/books, loads, carries, unloads or receives goods transported by heavy vehicle;

- owns or operates a heavy vehicle; or

- owns or operates heavy vehicle loading/unloading premises,

is part of the Chain and bound to comply with the CoR laws.

This policy includes a summary of the primary compliance obligations under the CoR laws. Further information regarding CoR responsibilities can be found – https://www.nhvr.gov.au.

Under the CoR laws, each party in the Chain can be held responsible and liable for breaches committed by another party anywhere along the Chain. In addition where a business or corporation is a party in the Chain, its directors, partners and managers can also be found guilty for failing to ensure compliance with the CoR laws by the business.

It is therefore essential that every party in the Chain complies with the CoR laws, to protect themselves and every other party in the Chain.

All parties in the Chain must :

- ensure, so far as is reasonably practicable, the safety of their ‘transport activities’ (means business practices and decisions associated with the use of vehicles and includes consigning goods for road transport; scheduling the transport of goods by road; packing, loading or unloading goods for road transport; transporting goods by road and receiving goods transported by road) relating to the use of a heavy vehicle or, in the case of Western Australia, any vehicle;

- take all reasonable steps to avoid any breach of the CoR laws;

- ensure that their actions/inactions do not result in, encourage, reward or provide an incentive for any other party in the Chain, including in particular any driver, to breach the CoR laws

- not make any request or enter into any contract which would cause, encourage or provide an incentive for any other party in the Chain, including in particular any driver, to breach the CoR laws.

Mass

Mass requirements may relate to the:

- gross mass of heavy vehicle or combination together with their loads

- mass on axles or axle groups of heavy vehicle or combination

- weight of any freight container and its goods.

Primary obligation –

Any load placed on a heavy vehicle or combination must not exceed the relevant mass limits (gross, axle, tyre or freight container limits) for that vehicle.

Specific Guidance

Parties in the Chain must be aware of or ensure that there are systems in place to verify the mass limits applicable to every heavy vehicle or, in the case of Western Australia, any vehicle used in their transport activities, including those applicable to any route which the heavy vehicle is scheduled to take and whether approved under any access permit or notice.

Before loading, the driver/Courier and Customer must exchange and record information on the mass of the planned load, including the mass of each component of the load (e.g. the mass of the load as marked on any equipment or packaging or as advised by the supplier/manufacturer).

Before loading, the driver/Courier and any person responsible for loading the heavy vehicle must ensure a loading plan is prepared and implemented, including the mass of the load and location and maximum applicable mass limits for all components of the load and vehicle.

If the planned load cannot be loaded onto the vehicle presented in compliance with the maximum applicable mass limits, it must not be loaded, or only loaded to the extent in compliance with the maximum applicable mass limits.

Before any loaded journey/part-journey is commenced:

- The mass of the loaded heavy vehicle must be weighed (e.g. using on board weighing equipment) OR

- The mass of the loaded vehicle must be calculated,

to ensure that it is within the maximum applicable mass limits for the heavy vehicle (GVM and axle limits).

A complying Container Weight Declaration must be provided to the driver/Courier in respect of any containerised load, before the vehicle departs.

Any equipment used to measure the mass of any loaded vehicle or component of any load must at all times be properly functioning and calibrated in accordance with any manufacturer’s recommendations and applicable standards.

Any party in the Chain, in particular Couriers, must ensure that the implementation of its mass management program is routinely monitored and any non-conformance events are investigated and remedied and that it conducts at least an annual re-assessment of the risks of non-compliance with mass requirements and the control measures implemented as part of its mass management program.

Dimension

Dimension requirements may relate to the dimensions (width, height, length, overhang) of a:

- heavy vehicle or combination (together with its equipment);

- component of a heavy vehicle or combination; or

- heavy vehicle’s load.

Primary obligation –

No heavy vehicle or combination (including any load) may exceed the prescribed width, height, length or overhang limits for that vehicle.

Specific Guidance

Parties in the Chain must be aware of or ensure that there are systems in place to verify the dimension limits applicable to every heavy vehicle or, in the case of Western Australia, any vehicle used in their transport activities, including those applicable to any route which the heavy vehicle is scheduled to take and whether approved under any access permit or notice.

Before loading, the driver and any person responsible for loading must exchange and record information on the maximum applicable dimension limits for the heavy vehicle, including those applicable to any route which the heavy vehicle is scheduled to take and whether approved under any access permit or notice.

Before loading, the driver/Courier and Customer must exchange and record information on the dimensions of the planned load, including the dimensions of each component of the load (e.g. including the dimensions of the load as marked on any equipment or packaging or as advised by the supplier/manufacturer).

Before loading, the driver/Courier must ensure a loading plan is prepared and implemented, including the dimensions of the load and location and maximum applicable dimension limits for all components of the load and heavy vehicle.

If the planned load cannot be loaded onto the vehicle in compliance with the maximum applicable dimension limits, it must not be loaded, or it may only be loaded to the extent in compliance with the maximum applicable dimension limits.

Before departing on any journey/part-journey every loaded vehicle should be inspected to ensure that the load:

- does not exceed the dimension limits of the vehicle or applicable on the planned route and

- is not likely in the ordinary and foreseeable course of transport to move or shift so as to become in excess of the dimension limits of the vehicle or applicable on the planned route.

Any party in the Chain, in particular Couriers, must ensure that the implementation of its dimension management program is routinely monitored and any non-conformance events are investigated and remedied and that it conducts at least an annual re-assessment of the risks of non-compliance with dimension requirements and the control measures implemented as part of its dimension management program.

Load Restraint

Load restraint requirements may relate to the restraint or positioning of a load or any part of a load:

- The restraint of any load, including its components, in or on a heavy vehicle

- The restraint of any load, including its components, within a freight container

- The restraint of any freight container in or on a heavy vehicle.

Primary obligation –

A load on a heavy vehicle or combination must not be placed in a way that makes the vehicle unstable or unsafe and must be secured so it’s unlikely to fall or dislodge from the vehicle.

Any method of restraint used must comply (at a minimum) with the National Transport Commission’s ‘Load Restraint Guide’ (Second Edition, 2004) (or any replacement or modification).

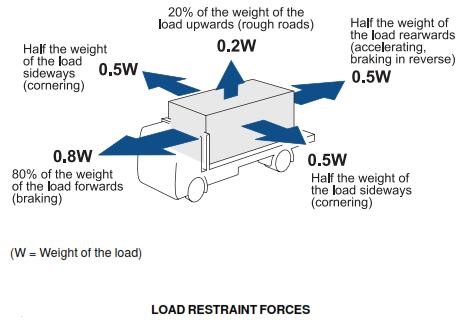

Golden rule – The load restraint system employed in/on a heavy vehicle or inside a freight container must meet or exceed the minimum regulatory Performance Standards contained in the National Transport Commission’s Load Restraint Guide, so that any load movement is limited, such that any shift does not:

- contribute to instability of the heavy vehicle or

- cause the load to become dislodged from the heavy vehicle,

when exposed to the forces shown below:

Extracted from the NTC ‘Load Restraint Guide’ (Second edition, 2004)

Note that these forces, and the forces that any load restraint system must be designed to meet or exceed, are equivalent to a low-speed collision between a heavy and light vehicle. That is, any load restraint system for goods in/on a heavy vehicle or in a freight container must be capable of sustaining a low-speed collision between a heavy and light vehicle.

In very limited circumstances, loads may be permitted to move relative to the vehicle. They include loads that are effectively contained within the sides or enclosure of the vehicle body (where side curtains do not qualify as a load restraint mechanism or enclosure, except for items of negligible (both individually and collectively if there are more than one such item) weight), such as:

- loads which are restrained from moving horizontally (limited vertical movement is permissible)

- very lightweight objects or loose bulk loads (limited horizontal and vertical movement is permissible)

- bulk liquids (limited liquid movement is permissible).

General guidelines for load restraint can be found in the National Transport Commission’s ‘Load Restraint Guide’ (Second Edition, 2004) (available at www.ntc.gov.au), the contents of which (including any replacement or modification) is incorporated into this policy as if it was set out in full.

Drivers remain primarily responsible for securing their load, including conducting a final load restraint compliance check before departure.

Before loading:

- A vehicle, the driver/Courier and any person responsible for loading the vehicle

- A freight container, the consignor/consignee and any person responsible for loading the freight container,

must ensure a loading plan is prepared and implemented, including the details of any approved load restraint system to be used.

If the planned load cannot be loaded onto the heavy vehicle or into a freight container in compliance with the Load Restraint Guide and approved load restraint system, it must not be loaded, or only be loaded to the extent in compliance with the Load Restraint Guide and any approved load restraint system.

Before:

- Any vehicle departs on any journey, every loaded vehicle

- Any loaded freight container is sealed, every load of any freight container,

should be inspected to verify that the load restraints applied to any load conform to the requirements of the Load Restraint Guide and any approved load restraint system.

Any party in the Chain, in particular Couriers, must ensure that the implementation of its load restraint management program is routinely monitored and any non-conformance events are investigated and remedied and that it conducts at least an annual re-assessment of the risks of non-compliance with load restraint requirements and the control measures implemented as part of its load restraint management program.

The following load restraint guidance is taken from the NTC ‘Load Restraint Guide’ (Second Edition, 2004):

General tips

- Ropes are extremely ineffective for restraining loads.

- Even though a rope might feel tight, the amount of tension in it is very low.

- The tension in a webbing strap is generally about 5 to 10 times more than a rope.

- Short chains are difficult to tighten properly with a ‘dog’, because they won’t stretch as much as a long chain, to allow the handle to be pulled down. Turnbuckles are better.

- A ‘curtain-side’ cannot restrain a load properly unless it is part of a certified load restraint system.

- The weight of the load alone cannot provide enough friction to restrain it during normal driving. Additional restraint must be used.

- Loading directly onto slippery steel decks, roof racks or A-frames should be avoided. Use wood or rubber to improve the grip.

Unitising packs and pallets

- Items of load can be bound together to form a single unitised load to make them easier to handle and restrain.

- Unitising methods include banding, strapping, gluing, stretch wrapping and shrink wrapping.

- Packers/Consignors of unitised loads should ensure that the size of the packs and the unitising method is appropriate to restrain individual items in the pack during transport. If the unitising fails during transport, the load can dislodge from the vehicle.

- Because pack strapping is tensioned from the top, the base of the pack may not be effectively consolidated. It is therefore important that the assembly and strapping system used ensures that the bottom layers are tightly packed

Securing packs

- Packs can comprise multiple layers or stacks of material, or bundles of individual lengths.

- Packs may be restrained by tie-down or containment.

- Unitising on its own may not be sufficient to restrain all items in a pack during transport.

- Layers can slide within a pack because of slippery surfaces or particles between the layers.

- Individual lengths can spear out from the centre of a pack because the external strapping does not clamp all of the internal lengths. In rectangular packs, the strapping forces often only clamp the outer lengths of the pack. In such cases spearing can be prevented by end wrapping or blocking.

- When bundling lengths, especially circular items, the strapping will cause the pack to form a circular shape. Generally if the lengths are initially strapped in any other shape, external forces could cause the bundle to change shape and the strapping to loosen. The exceptions are triangular packs of three circular sections and hexagon packs of seven circular sections.

- Individual items can become dislodged from a stack on a pallet because the strapping forces are not evenly spread throughout the pack. Items often become dislodged from the upper outer edges of an inadequately unitised pack.

- Where there is a possibility that items can dislodge from a pack, additional restraint (by blocking or containment) must be used.

- Some packs are an unstable shape for restraint in the forward direction (for example, ingots, bricks). These packs must be prevented from tipping forward by placing them against barriers or other packs or by other methods.

Loads on pallets

Unitised load resting on pallet

- Where unitising is not sufficient to restrain the product on the pallet during transport, the product requires restraint as well as the pallet.

- If the pallet is restrained by tie-down, the combination of the unitising and tie-down must prevent all items on the pallet from becoming dislodged. If an item could dislodge, additional restraint must be used.

Unitised load secured to pallet

- Where the items of load are adequately unitised and secured to the pallet, the load can either be tied down or contained.

Load loosely stacked on pallet

- Items of loads loosely stacked on a pallet can be restrained completely by containment by the vehicle structure (for example gates, headboards, racks) or other parts of the load.

- Alternatively, external tie-down lashings can be used provided all parts of the load are restrained by the lashings. If the lashings cannot restrain every item, the load must be restrained by the vehicle structure or other parts of the load.

Restraining Packs and Pallets

- Packs and pallets can be restrained by combinations of tie-down and blocking, or in some cases, by direct restraint (headboards and gates) only.

- Tarpaulins and curtain sides alone should never be considered as a total pallet restraint system, unless they have been specifically designed and certified for the particular type of load.

- Tie-down lashings over the top of packs and pallets can readily provide the necessary rearward and sideways restraint, in most cases. However, to reduce the number of tie-down lashings to a practical number for forward restraint, the front of the load can be blocked.

- The use of rubber load mat can greatly reduce the number of tie-down lashings required especially for loads with slippery surfaces.

- Additional restraint can be provided by blocking the full pallets with an empty pallet against a headboard or loading rack, provided items placed on each pallet are tied down to the pallet in a way that means the performance standards are met, or restraining the headboard or rack with direct lashings.

Speed Management

Speed may relate to:

- The maximum speed limit applicable to a heavy vehicle

- The maximum speed limit for any road

- The safe speed for any particular vehicle, including having regard to the characteristics of its load.

Primary obligation –

No driver can drive and no person can request a driver to drive if to do so would result in the driver breaking the applicable speed limits.

It is an offence for any person to offer any encouragement, incentive or reward for a driver to drive in breach of the applicable speed limits.

Speed regulated heavy vehicles must be fitted with properly calibrated and functioning speed limiters.

Specific guidance

Any person scheduling a vehicle journey or setting any time for pick up, journey or delivery time must ensure that its schedule can be completed in time and at all times in accordance with any legal road speed limit, including:

- allowing reasonable time for any necessary site induction, loading, driving, rest time and waiting

- having in place procedures to respond to any journey delays (including weather, traffic, queuing, mechanical breakdown or fault or site delays).

All speed regulated heavy vehicles must be fitted with properly calibrated and functioning speed limiters. Proper calibration and functioning of speed limiters must be verified, including through the use of the compliance monitoring measures outlined below.

Any party in the Chain, in particular Couriers, will ensure that its work practices permit the scheduling of journeys so that they can be completed in time and at all times in accordance with any legal road speed limit, including allowing time for or having in place procedures to respond to any journey delays (weather, traffic or site).

Any party in the Chain, in particular Couriers and Customers, will ensure that no demand is placed on any driver in relation to any pick-up, delivery or transit time which would force, encourage, induce or reward any driver for exceeding any legal road speed limit.

Any party in the Chain, in particular Couriers, must ensure that the implementation of its speed management program is routinely monitored and any non-conformance events are investigated and remedied and that it conducts at least a re-assessment of the risks of non-compliance with speed requirements and the control measures implemented as part of its speed management program after any speed incident and, at a minimum, annually.

Fatigue Management

Fatigue may relate to:

- Maximum permitted work and rest hours for drivers

- Drivers being adversely impacted by fatigue, regardless of falling within their Maximum permitted work and rest hours.

Primary obligation –

No driver can drive and no person can request a driver to drive if to do so would result in the driver breaching their applicable work/rest hours limits. Work and rest requirements set out the maximum work period and minimum rest periods that must be observed.

Certain drivers are required to maintain work diaries and records of their work/rest hours.

It is an offence for any person to offer any encouragement, incentive or reward for a driver to drive in breach of their relevant applicable work/rest hours limits.

Parties in the Chain must ensure that the terms of any business practices, consignment, driver’s schedule or loading arrangements will not cause a driver to drive whilst fatigued.

A fatigue-regulated vehicle is a heavy vehicle or combination of more than 12t Gross Vehicle Mass.

Work and rest hours

The CoR laws provide for three work and rest hours options (more details can be found here – https://www.nhvr.gov.au):

- Standard hours are the work and rest hours allowed in the HVNL for all drivers who are not operating under National Heavy Vehicle Accreditation Scheme (NHVAS)accreditation or an exemption. They are the maximum amount of work and minimum amount of rest possible that can be performed safely without additional safety countermeasures.

- Basic Fatigue Management (BFM)/Advanced Fatigue Management (AFM).

Work diaries

Driver work diaries – All drivers of fatigue-regulated heavy vehicles who drive more than 100km from their home base or operate under BFM/AFM must complete a work diary to record their work and rest times unless they have a work diary exemption (either through a notice or permit).

Work time and rest time must be counted in a certain way. Understanding the rules for counting time will help drivers manage work and rest times and assist other responsible parties in the supply chain comply with their duties to manage work and rest time and prevent driver fatigue.

Work time includes all tasks to do with the operation of the fatigue-regulated heavy vehicle, including driving, loading/unloading and associated paperwork. Rest time is all time that is not work time.

Record keeping requirements

Record keepers must keep a record of specific information for drivers of fatigue regulated heavy vehicles. A record keeper may be the:

- employer, if the driver is employed;

- accredited operator, if the driver is working under Basic Fatigue Management or Advanced Fatigue Management accreditation; or

- driver (as a self-employed or owner driver).

For each driver the record keeper must keep:

- the driver’s name, licence number and contact details;

- the dates fatigue regulated heavy vehicles were driven;

- the registration number of the vehicle(s) driven;

- the total of each driver’s work and rest times for each day and each week;

- copies of duplicate work diary daily sheets (if applicable);

- driver’s rosters and trip schedules (including changeovers);

- driver timesheets and pay records; and

- any other information as required as a condition of an accreditation or exemption (such as driver training and health assessments).

Drivers must provide their record keeper with their relevant work and rest hours totals and any other relevant vehicle information the record keeper may not reasonably have access to (registration numbers, dates the driver worked, etc.). The record location is usually the driver’s base. All records must be kept for three years after they are created.

Specific guidance

Any party in the Chain, in particular Couriers, will ensure that its work practices permit the scheduling of journeys so that they can be completed in time and at all times in accordance with any applicable fatigue laws, including allowing time for or having in place procedures to respond to any journey delays (weather, traffic or site).

Any party in the Chain, in particular Couriers and Customers, will ensure that no demand is placed on any driver in relation to any pick-up, delivery or transit time which would force, encourage, induce or reward any driver to drive whilst fatigued or in breach of any applicable fatigue laws.

Any party in the Chain, in particular Couriers, must ensure that the implementation of its fatigue management program is routinely monitored and any non-conformance events are investigated and remedied and that it conducts at least a re-assessment of the risks of non-compliance with fatigue requirements and the control measures implemented as part of its fatigue management program after any fatigue incident and, at a minimum, annually.

Maintenance Management

Heavy vehicle maintenance and roadworthiness refers to:

- Compliance with manufacturer’s recommendations and standards

- Compliance with heavy vehicle standards

- Compliance with Australian Design Rules

- The conduct of scheduled and unplanned routine maintenance

- Roadworthiness and fitness for duty of all equipment.

Primary obligation –

Any vehicle/combination used to carry road cargo must meet Australian design standards and be maintained in a roadworthy state.

Those responsible for a vehicle must ensure that proper and routine inspections are carried out and any necessary maintenance and repairs are conducted.

Specific guidance

All owners and operators of any vehicle are responsible for ensuring that the vehicle is equipped and operated in accordance with any design and licensing requirements, conditions and standards.

Any vehicle used for the transport of goods by road must be registered and maintained in a roadworthy condition and be subject to appropriate pre-trip roadworthiness and safety inspections.

Any driver must be appropriately qualified and licenced to operate any vehicle and equipment provided.

Any vehicle not in accordance with the foregoing should not be used to transport any goods or driven on the road at all.

Any responsible person for a vehicle, in particular Couriers, must ensure that the implementation of its maintenance management program is routinely monitored and any non-conformance events are investigated and remedied and that any responsible person for a heavy vehicle conducts at least an annual re-assessment of the risks of non-compliance with maintenance management requirements and the control measures implemented as part of its maintenance management program.

General Compliance Issues

All transport documentation must be accurate and not be false or misleading in a material particular so far as it relates to the mass, dimension or loading of any goods or fatigue and work/rest management.

If any person thinks that the terms of any consignment, requirement or practice could result in any breach of the CoR laws, it is their responsibility to make investigations, seek clarification from the person(s) immediately up the Chain from them and not permit a driver to drive until they are satisfied that no such breach will occur.

Subcontracting

In the event that a Courier is permitted to subcontract all or any part of any Booking under the Platform, the subcontracting terms under Zoom2u’s Chain of Responsibility Terms will apply.

Consequences of Breach

Upon becoming aware of any breach or suspected breach of any mass, dimension, load restraint, fatigue, speed or maintenance requirement, Zoom2u may report the breach to the relevant authority (e.g. RMS in NSW, VicRoads in Vic) and retain records of the breach.

Zoom2u also reserves the right to issue a ‘show cause’ notice in relation to any breach or suspected breach of any mass, dimension, load restraint, fatigue, speed or maintenance requirement.

Upon becoming aware of any breach or suspected breach of the CoR laws, Zoom2u’s CoR Terms or this policy, Zoom2u reserves the right, in its sole and absolute discretion:

- not to pay any amounts which would otherwise be owing to the Courier under the Zoom2u Courier Terms and Conditions in circumstances of breach of the HVNL;

- suspend the User’s access to the Platform without further payment until such time as the breach is remedied to the satisfaction of Zoom2u; and

- terminate the User’s access to the Platform with immediate effect by giving notice in writing to the User.